Full automation in CPQ (Configure, Price, Quote) systems has been an aspirational goal for years....

Why Dual BOM Management in CPQ is The Future of Manufacturing

Hooked on BOM? Here's a bold claim: traditional manufacturing methods are out! The future? Dual Bill of Materials (BOM) management in Configure, Price, Quote (CPQ) solutions. Let me paint a clearer picture.

As you configure your morning coffee (extra shot of espresso, oat milk, and a touch of cinnamon), you probably aren’t thinking about the BOMs that went into it. But what if I told you that, in the world of manufacturing, a simultaneous approach to BOMs is revolutionizing how products are made and sold? Intrigued? Let's dive into why dual BOM management in systems like Tacton CPQ isn't just a luxury—it’s an absolute necessity for the modern manufacturer.

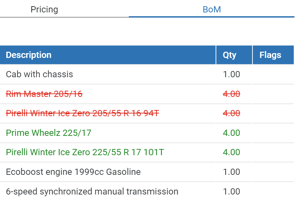

Real-time Relevance: Picture this—you're a sales rep, and as you dynamically craft a product configuration for your client, the manufacturing department instantly receives updates. This isn’t a scene from a sci-fi movie but a reality with dual BOM management. By managing the Manufacturing Bill of Materials (MBOM) and Sales Bill of Materials (SBOM) simultaneously, the bridge between what’s sold and what’s produced is not only built but fortified.

Efficiency on Steroids: Remember the last time you placed an order and it took eons to get a confirmation? With the MBOM ready to roll the moment a sale is confirmed, production can hit the ground running. The days of translating sales configurations into manufacturing lists are history.

Saying Adios to Errors: Dual BOM management is like having a super vigilant guardian that’s always on the lookout. By maintaining both BOMs in real-time, discrepancies between sales configurations and manufacturing are minimized. Think of it as having a safety net, ensuring that what you promised is precisely what gets delivered.

ERP Integration - Smooth as Silk: Ever tried fitting a square peg in a round hole? Traditional integration with Enterprise Resource Planning (ERP) systems can feel just like that. But with both BOMs managed within the CPQ, integration is as seamless as pouring cream into coffee.

Redefining Customer Experience: With a real-time peek into manufacturing constraints and capabilities, sales teams can up their game, offering precise delivery dates. Customers don’t just get products; they get trust and reliability.

Inventory - Always On Point: Nothing's worse than realizing a key component is out of stock, right when you need it. Dual BOM management ensures inventory levels mirror the sales configurations being generated. It’s like having a personal assistant that always knows what's needed and when.

Adapting with Panache: Change is the only constant. As products evolve or new ones emerge, a dual BOM management approach ensures that the CPQ system isn't just reactive but proactive.

In wrapping up, if the world of manufacturing was a chess game, think of dual BOM management as the queen—the most powerful piece on the board. It’s not just about keeping up with the times; it’s about being two steps ahead. As products get more complex and customer demands more nuanced, this simultaneous approach isn’t just a nice-to-have—it’s the linchpin of a successful manufacturing strategy.

So, the next time you take a sip of your perfectly configured coffee, remember there's a whole world out there redefining how products come to life, one BOM at a time.